YOUR EXPERT FOR SPECIALIZED MECHANICAL ENGINEERING.

For over 30 years lebensmitteltechnik.at has been your professional partner in food production technology.

Our machines

More than 30 years ago we specialized in constructing special mechanical devices and have constantly developed our range of machines since then.

Together with and for our customers we have been constructing and building a considerable number of innovative machines and, therefore, can meet market needs with technic innovations.

Our offers include coextrusion technique to produce filled and unfilled dumplings 10 - head filling flow dividers for the portioning of food products as well as various machines and technological products for dumpling and croquette shape production.

Our rounding belts give your dumplings their perfect shape and our transportation belt take your products to the cooking device, the fryer or the freezer.

ALL ABOUT OUR MACHINES

FILLING - SHAPING - TRANSPORTATION

HE 1200 - KOEX

Type: 1 - 2 - 4 - 6 - 9 heads

FOR PERFECTLY FILLED AND UNFILLED PRODUCTS WITH SINGLE OR MULTIPLE FILLINGS.

Coextrucion technology form head

Dumplings - Gnocchis - Croquettes

HE 1200 KOEX is a front-end divice for shaping, portioning and filling of products and attachable to all standard filling machines.

Production quantity: 140 to 1.260 dumplings per minute.

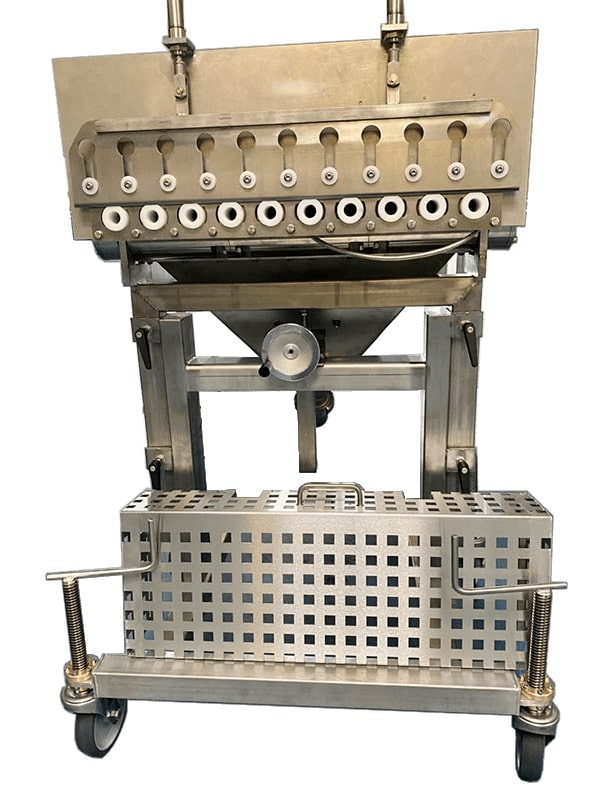

FSTA filling - flow divider with or without cutting device

Type: 2 - 4 - 6 - 8 - 10 heads

FOR THE PRODUCTION OF CROQUETTES, CEVAPCICI AND ALL KINDS OF POTATO, MEAT AND CHEESE PRODUCTS

The filling flow divider with cutter is a front-end device for all standard vacuum filling machines, with 2 to 10 filling flows for the further processing of all kinds of pasty material.

Production quantity: up to 1.100 pieces per minute

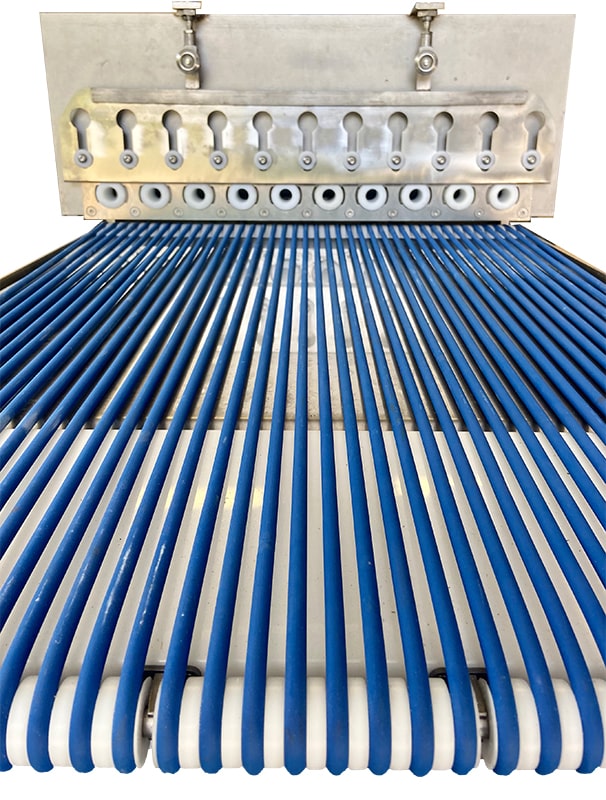

ORB universal O-ring belt

Type: 700-600 / 600-500 / 500-400 millimeter

FOR TRANSPORT AND COORDINATION OF ALL PRODUCTS IN AN EXACT WIDTH

The ORB universal o-ring belt is a front-end device for all standard filling machines and filling flow dividers for the further transport to the cooker, fryer or freezer.

Transport width from: 800mm width to 600mm width (example)

NRB - Rounding belt

Type: NRB 1 - 2

FOR THE PERFECT FINAL ROUNDING OF FILLED AND UNFILLED DUMPLINGS

For the final rounding of dumplings: from 10 up to 200 grams or heavier.

Floured, greased or watered - the NRB rounding belt puts your products in a perfectly round shape.

UKF - universal dumpling former

With or without filling - flow divider

Type: 1 - 2 - 4 - 8 - 10 heads

FOR ALL UNFILLED PRODUCTS SUCH AS CROQUETTES, CEVAPCICI, DUMPLINGS, POTATO NOODLES, FRESH CHEESE, QUARK AND MANY MORE

The UKF - universal dumpling former is a front-end device for all standard vacuum filling machines which portions to the gram in many different shapes.

Various pasty material as well as bread and potato dough can be processed into ball, cone, oval and croquette shapes.

Vacuum-filling technology

In cooperation with

HTS-Systems

Fleischereimaschinen

www.hts-systems.at

Contact

Helmut Ebner Lebensmitteltechnik

Jägerweg 4

5301 Eugendorf